Engineered Thermoplastics. Delivered with Precision.

Explore custom-molded, extruded, and assembled products built to exacting standards—with in-house design, compounding, tooling, and U.S. manufacturing from start to finish.

See What We’re Built For

Discover how our thermoplastics expertise turns complex requirements into reliable, high-performance solutions.

Start Your Project

Have a project in mind? Let’s work together to build a high-performance solution.

Your Single Source for Thermoplastic Innovation: End-to-End

At Flex Technologies, performance isn’t an afterthought—it’s built into everything we do. From proprietary Polyflex PVC compounding to precision extrusion, molding, and final assembly, our vertically integrated model brings speed, consistency, and control to every phase of production. With in-house tooling and a responsive engineering team, we solve complex challenges faster, reduce risk, and deliver thermoplastic solutions that meet the highest standards of durability and reliability.

As a proud U.S.-based manufacturer of custom plastic assemblies, we’re committed to helping manufacturers succeed through tailored solutions, shorter lead times, and dependable quality. For companies seeking a trusted, OEM partner for thermoplastic components or complete system builds, Flex Technologies offers the capabilities and collaboration to support your success.

Whether you're sourcing custom plastic parts made in the USA or looking for an agile partner to deliver end-to-end solutions, Flex Technologies delivers quality products—first time, on time, every time.

Explore Our Product Categories:

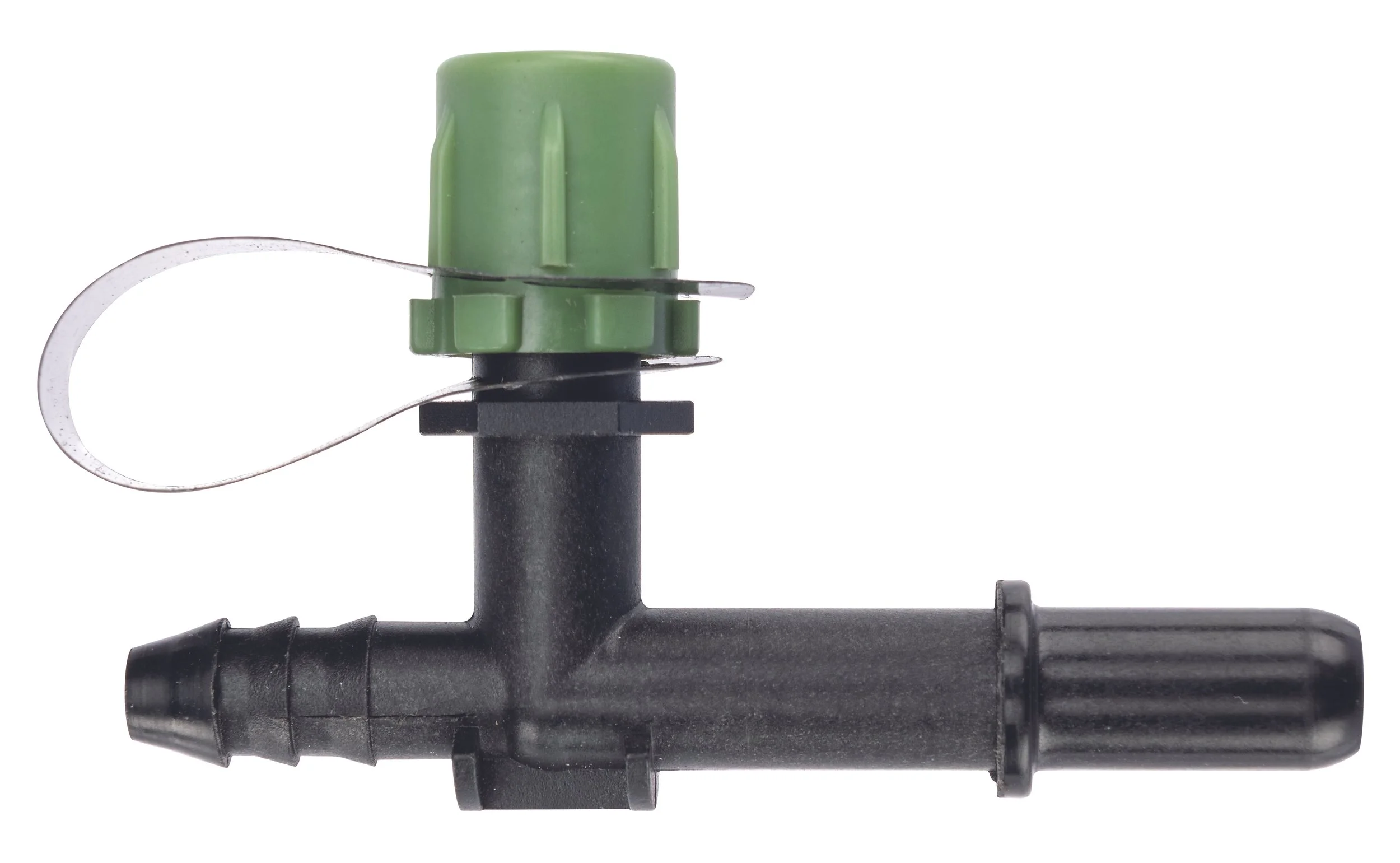

Assembled Products

Precision assemblies engineered for performance.

At Flex Technologies and Polyflex, our goal is to set the standard for quality, speed, and precision. This commitment has made us a trusted partner in the design and manufacturing of custom plastic assemblies and thermoplastic fluid assemblies since 1975.

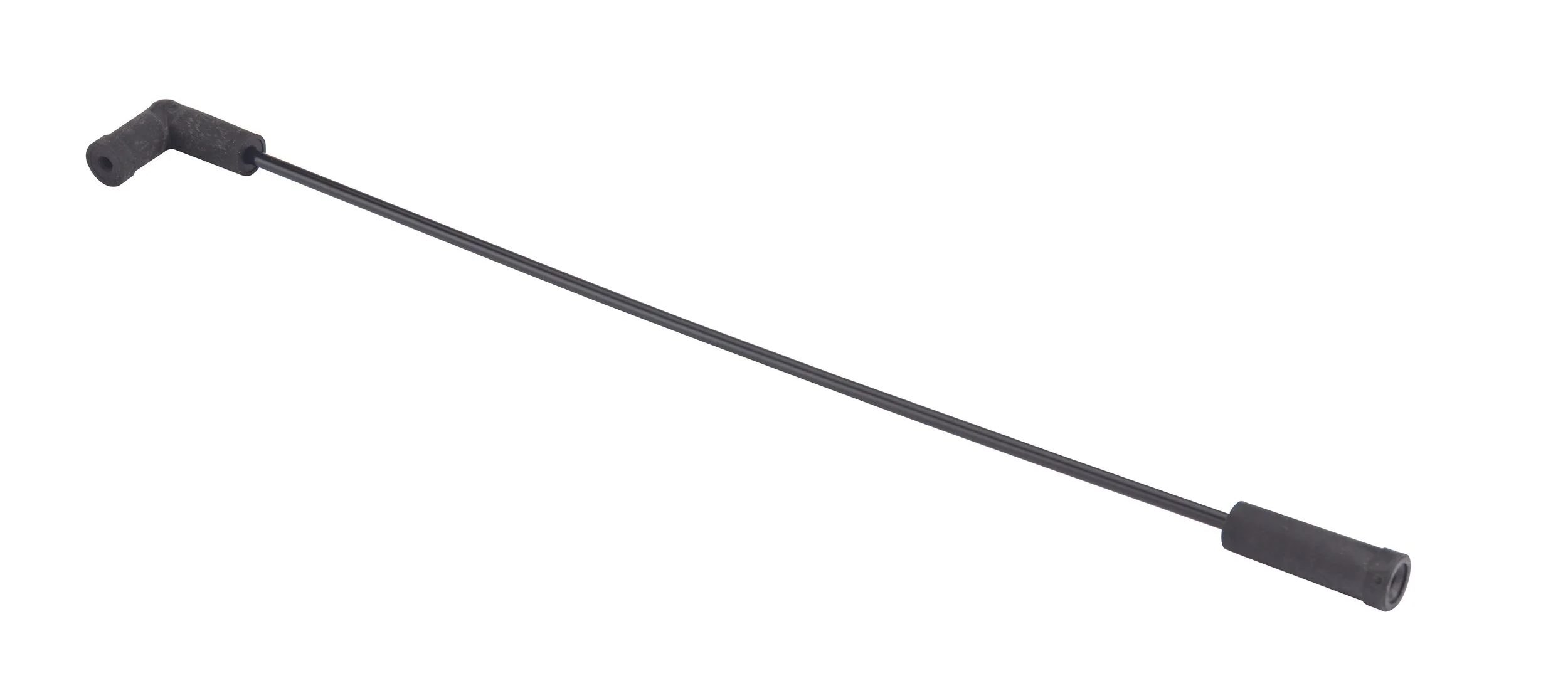

Our specialties include vacuum, air, fuel, and vapor assemblies, as well as throttle, combo, and automotive cable systems. These value-added assemblies are designed as ready-to-install OEM systems, reducing complexity and streamlining production for our customers.

Whether we're forming tubing, bonding components, or executing complex routing, we combine automated processes with skilled manual assembly to ensure repeatability, reliability, and performance. We also offer expert thermoplastic tube forming, plastic welding services (USA), injection and shuttle molding, and extrusion to support fully integrated fluid assemblies made in America. All assemblies undergo rigorous testing using advanced equipment to meet the most demanding specifications.

Process Capabilities:

Thermoplastic Tube Forming

Injection and Shuttle Molding

Advanced Manual & Automated Assembly

In-House Tooling & Prototyping

Spin-welding & Sonic Welding

Laser Etching

Dimensional Scanning

Typical Applications:

Vapor Emission Assemblies

Carbon Canisters

Fuel Emission Vapor Lines

Sunroof Drain Tubes

PVC & Vacuum Assemblies

Fuel Line Assemblies

Bring Your Project to Life

Let’s turn your specs into production-ready solutions.

Learn More About Our Process

See how our integrated approach delivers better results.

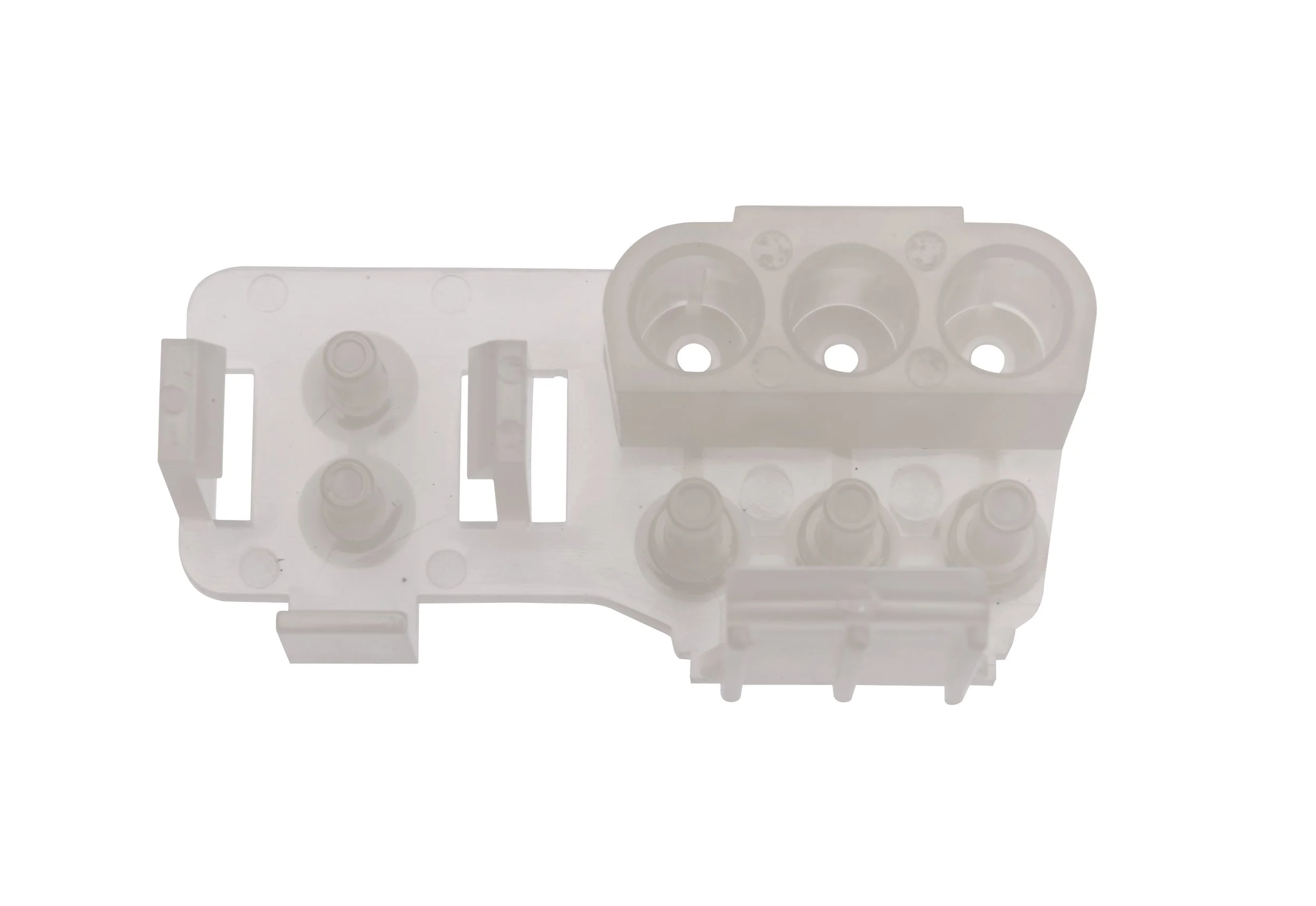

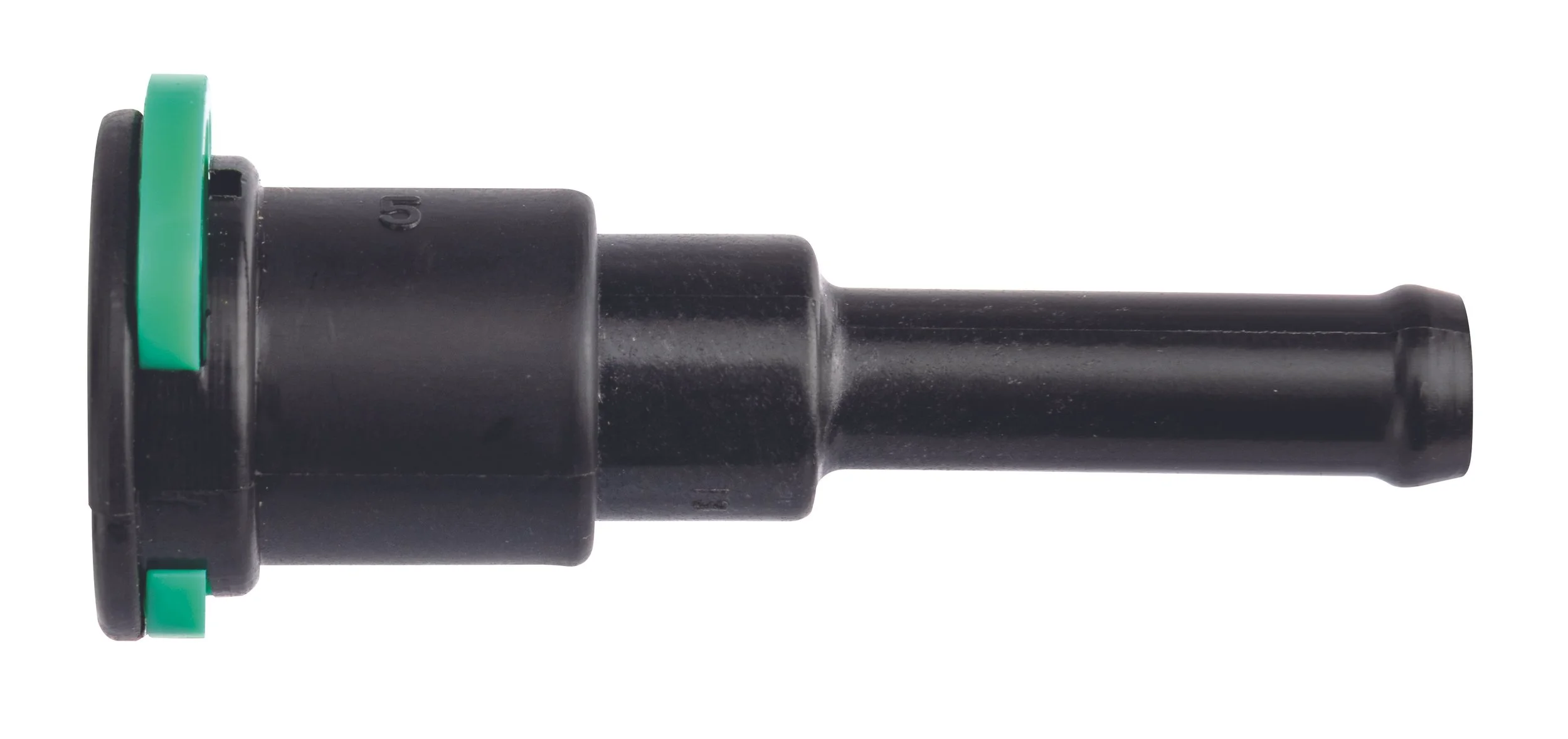

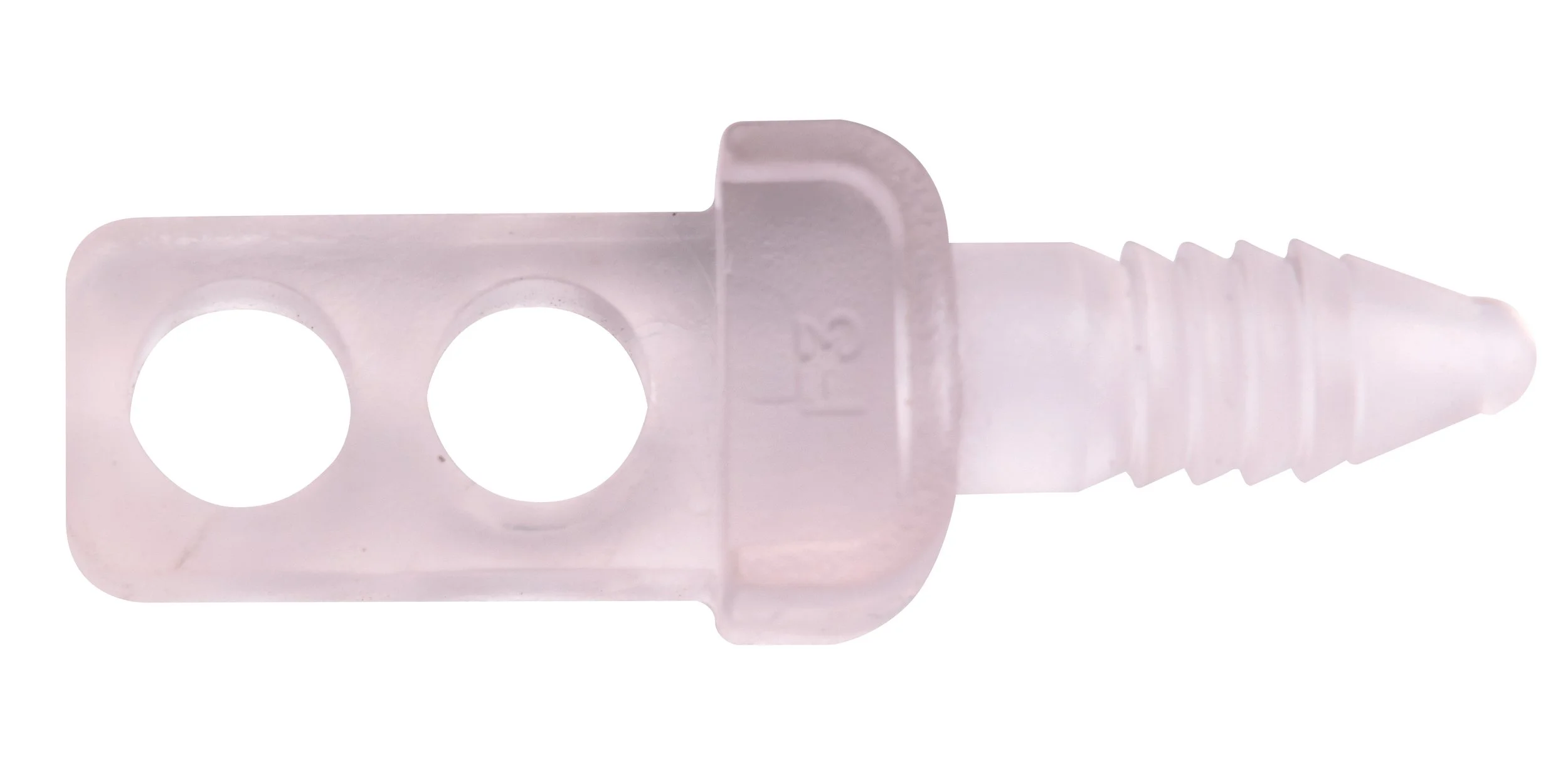

Injection Molded Components

Close-tolerance, USA-made parts that support critical applications.

Backed by five decades of engineering and manufacturing experience, Flex Technologies delivers high-performance, precision-molded thermoplastic components built to meet the most demanding standards. From complex geometries to tight-tolerance requirements, we combine technical expertise with advanced in-house capabilities to produce parts that perform—every time.

Our facilities in Ohio and Tennessee house presses ranging from 85 tons to 440 tons, supporting a range of USA- made injection molded parts and varied molding techniques, including shuttle molding—a method that allows us to mold multiple components or overmold parts efficiently within a single cycle. This approach is ideal for increasing throughput and consistency in high-precision assemblies.

Process Capabilities:

Close-Tolerance Injection Molding

In-House Tooling & Machining

Short-Run & High-Volume Production

3-D printing

Common Components:

Custom & Standard Quick Connects

Fuel Line Valves (Slosh/Shutoff)

Adaptors, Tees, and Ys

Fuel Vent Valves

Vapor Elbows

2-1/4” & 3-1/2” OPE Fuel caps

Let’s Build Something Better

Have a concept or challenge? We’ll create a production-ready solution.

See What Sets Us Apart

See how our integrated approach delivers better results.

Custom Extruded Products

Engineered extrusions that deliver strength, flexibility, and chemical resistance.

Since our founding in 1975, extrusion has been a cornerstone of Flex Technologies’ thermoplastics expertise. We specialize in PVC extrusion made in the USA, producing high-performance tubing and profiles tailored to exacting material, size, and performance specifications. With in-house compounding capabilities, we customize material formulations to meet the demands of diverse industries—from marine and automotive to lawn and garden.

A standout product in our extrusion portfolio is our weighted aeration tubing, engineered for durability and reliable performance in demanding environments. We also produce clear PVC tubing, marine rub rails, and other OEM-specific profiles—each designed for flexibility, strength, and chemical resistance.

While we do not produce reinforced conduit—a specialty of many of our valued Polyflex customers—we do offer custom extrusion capabilities for a wide variety of tubing constructions and material combinations.

Our Midvale, Ohio facility features in-house tooling, responsive prototyping, and consistent production quality to keep your project on time and on spec.

Process Capabilities:

Standard & Custom Extrusions

Braided, Lay-Wire & Flat-Wrap Reinforcement

Rapid Prototyping & In-House Tooling

Typical Applications:

Weighted Aeration Tubing

Marine Rub Rails

Reinforced PVC Conduit

Rigid Nylon Tubing

Bring Us Your Challenge

From the first idea to the final part, we’re here to help you move fast and build smart.

Discover the Flex Difference

See what sets our integrated approach apart from the rest.